If you are paying overboard for PCB designs, there is an alternative. Robin Mitchell is a Masters of Engineering student who has launched his own business producing low-cost PCB boards for students and consumers alike.

“Several years ago I began to create more elaborate electronic projects”, says Robin, who juggles his studies at the University of Warwick with running Mitch Electronics in his spare time and during the holidays. “With complexity comes more wires which eventually meant I needed PCBs. I looked for the best price but the smallest I could find was £30. And what if the board was faulty due to an error I could easily make? I needed another solution, so I decided to create my own PCBs.”

That was two years ago, and from a hobby he realised there was a gap in the market for anyone with the technical expertise and entrepreneurial spirit to fill it. While some companies charge £40 to manufacture a single PCB there is no guarantee the finished product does not contain errors, and there are further risks regarding intellectual property for products in development. “Nothing is stopping the manufacturer from stealing your design”, Robin told us. “I wanted to offer a service that would not only enable customers to have their PCBs manufactured to a high quality but to have the peace of mind that all the served files associated with the PCB design remain confidential.”

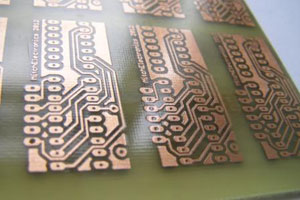

Since he formed Mitch Electronics in 2010, Robin has worked hard to perfect the various etching techniques. “Like most people I use the toner transfer method, but my two years research into homebrew PCBs has allowed me to refine the process and I am currently able to make double sided PCBs, trace width down to 7mil (with great care), solder masks and basic silk screens. I also get considerably lower failure rates through my own bespoke methods and processes.” Solder masks and silk screens enable the production of boards which are of better quality and are significantly easier to solder.